Sand Casting is the most common metal casting process. In this process molds are made of sand and mixed with a bonding agent such as clay, then compacted around the three-dimensional pattern.

This approach is suited to all kinds of ferrous and nonferrous alloys, as light as 100 grams (0.2 lbs) with little or no weight limitations.

US Castings offers various sand casting processes:

Hand molding:

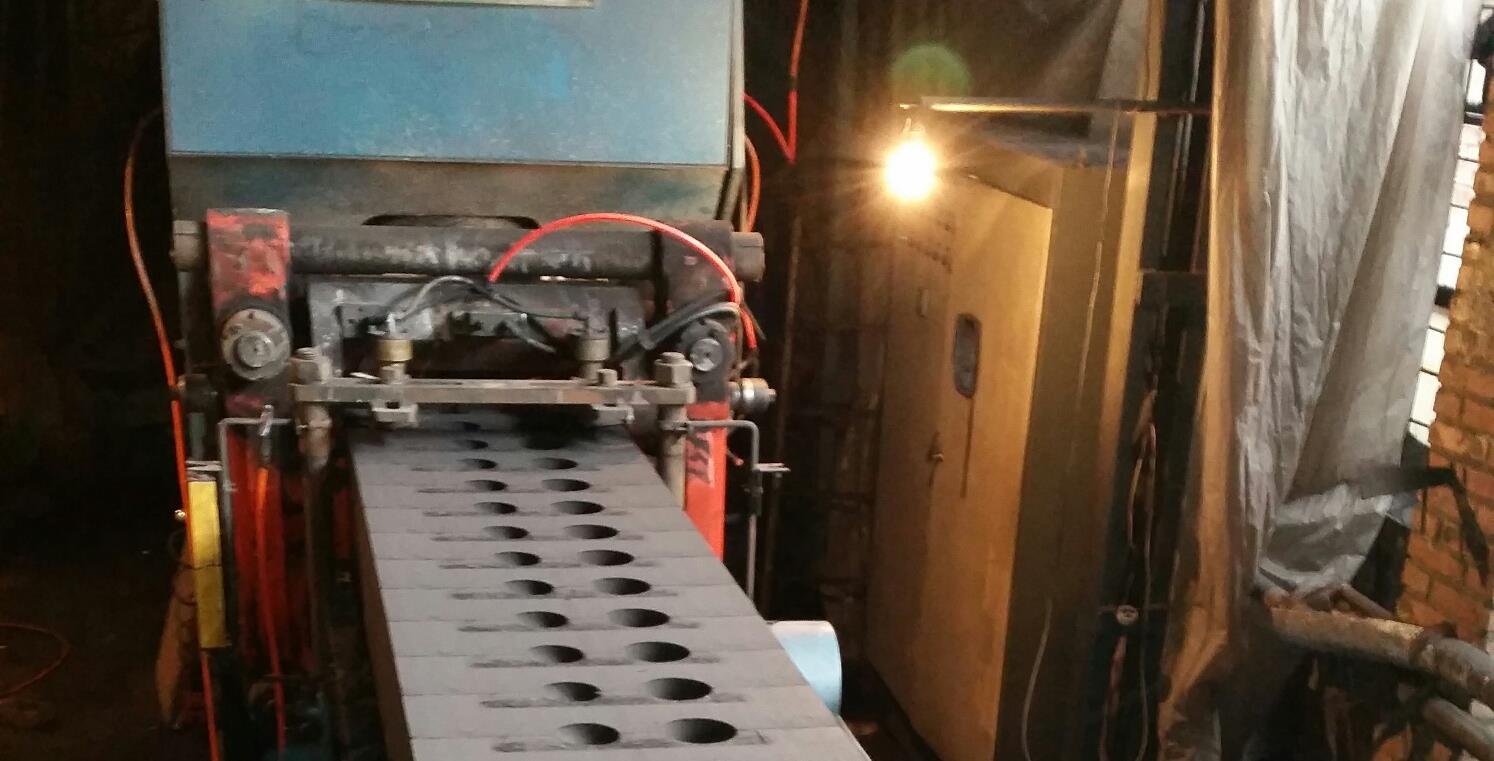

Resin sand mixer:

| *Hand molding (CT9-CT12) | Semi-Automatic molding (CT9) | Horizontal molding machine (CT8) | Vertical molding machine (CT7) | BBasic dimension (mm) |

| 1.5-4.2 | 1.5 | 1 | 0.7 | 1-10 |

| 1.6-4.4 | 1.6 | 1.1 | 0.78 | 10-16 |

| 1.7-4.6 | 1.7 | 1.2 | 0.82 | 16-25 |

| 1.8-5 | 1.8 | 1.3 | 0.9 | 25-40 |

| 2-5.6 | 2 | 1.4 | 1 | 40-63 |

| 2.2-6 | 2.2 | 1.6 | 1.1 | 63-100 |

| 2.5-7 | 2.5 | 1.8 | 1.2 | 100-160 |

| 2.8-8 | 2.8 | 2 | 1.4 | 160-250 |

| 3.2-9 | 3.2 | 2.2 | 1.6 | 250-400 |

| 3.6-10 | 3.6 | 2.6 | 1.8 | 400-630 |

| 4-11 | 4 | 2.8 | 630-1000 | |

| 4.6-13 | 4.6 | 3.2 | 1000-1600 | |

| 5.4-15 | 5.4 | 1600-2500 |

* These tolerances also apply to steel castings

US Castings’ engineering department is available to consult on geometric complexity, surface finish, cost and other factors. US Castings’ expertise in Value-Engineering will help to achieve the desired result at the lowest possible unit or overall cost.